Features

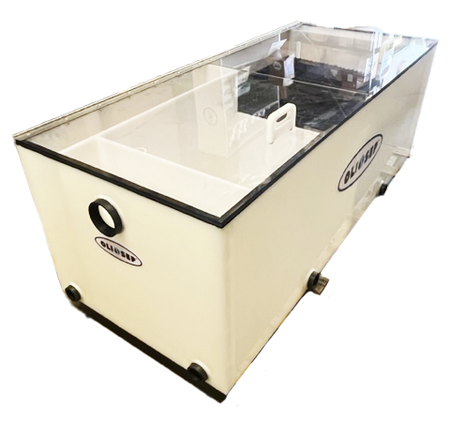

• Sludge trap built-in

• Polyethylene protection covers

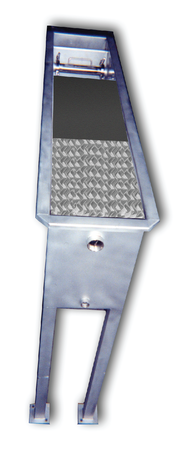

• Possibility to incorporate a by-pass directly within the equipment structure

• High storage capacity for separated products

• High mechanical resistance and corrosion protection

• Light and easy to install and maintain

• Totally watertight

• Without power consumption

• Low cost

• Without odors with a correct ventilation

Characteristics

To comply with current legislation, Grease Separators should be installed in these places:

• Restaurants

• Canteens

• Hotels

• Schools

• Bars

• Residential areas

• Camping parks

• Laundries.

• Any site with high quantity of grease and oil.

Operation

Grease Separators do not need any power consumption; it’s based on materials gravitational separation with different densities of water.

Heavier materials (sludge, sand, etc) settle into the Sludge Trap compartment and are trapped there. This compartment also holds Grease that easily floats. For the separation zone goes water and substances lighter than water, including grease which will be separated.

The grease will accumulate on the surface, while the clean water goes out at a level that does not allow the mixing of the phases.

Maintenance

Grease Separators do not need special care from a structural point of view, due to the high resistance and corrosion protection of the material from which they are made. Grease Separators should be inspected, emptied, cleaned and refilled with clean water.

| Part Number | Flow Rate | Grease Capacity |

| ER-840010 | 10 GPM, 90 L/min | 20 lbs, 9 kg |

| ER-840015 | 15 GPM, 190 L/min | 30 lbs, 14 kg |

| ER-840020 | 20 GPM, 380 L/min | 40 lbs, 18 kg |

For complete model information, view PDF brochure.